Protective Properties

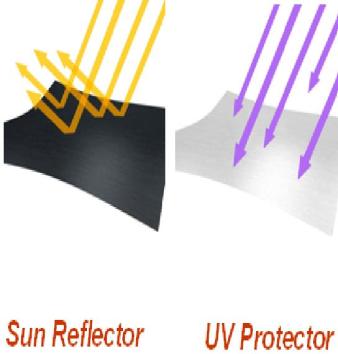

- UV Protection: Sunburn, SPF factors and ratings can be incorporated into fabric dyes,ceramic fibres have natural protection, fibres and laundry detergent, tighter and heavier construction allows further protection.

Unknown , (2000), Masood Textile Mills [ONLINE]. Available at:http://www.masoodtextile.com/research/special_finishes/special_finishes.php [Accessed 03 December 14].

- Fire and Spark Resistance: Emergency services, carpets and upholstery protected by law, amarmid/ glass/ carbon/ wool fibres have some natural resistance, chemical finishes can be applied, new ‘smart’ responses are heat shielding, metal coatings and shape memory

Unknown , (2004), Scotch_Guard_Flame_Retardant_On_Fabric_Shield [ONLINE]. Available at:http://www.alibaba.com/product-detail/Scotch-Guard-Flame-Retardant-On-Fabric_114863836/showimage.html [Accessed 03 December 14].

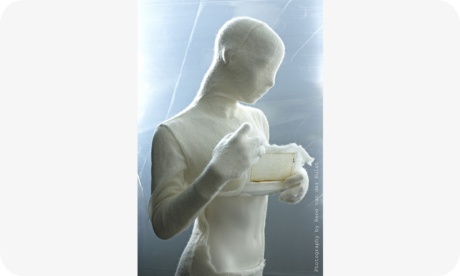

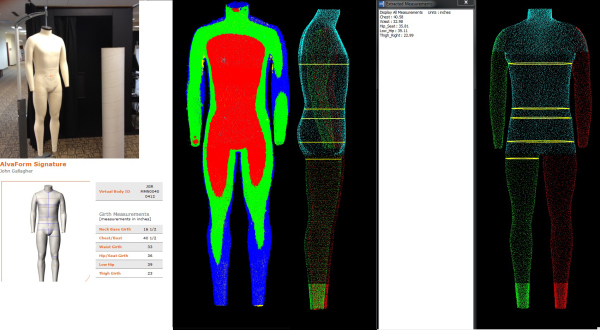

- Protection and Mobility: MIT Researchers using shape memory, second skin for space suits, protects but doesn’t limit movement and remembers shape of wearer

Revzilla, (2008), icon_device_textile_jacket_detail [ONLINE]. Available at:http://blog.revzilla.com/2012/08/icon-device-leather-and-textile-jacket.html [Accessed 03 December 14].

- Impact resistance: Aramid fibres of Cordura and Kevlar lead the way, ballistic protective body armour is lightweight, breathable and practical, stab-resistance uses aramid and lamination allowing the fabric to ‘heal’.

Textile World, (2009), SpecialtyDowSrange [ONLINE]. Available at:http://www.textileworld.com/Issues/2009/July-August/Nonwovens-Technical_Textiles/Observations_Of_Changing_Technology [Accessed 03 December 14].

- Weatherproof: Intelligent solutions and nano-technology, breathable laminates such as Gore-tex, 100% cotton and pure wool can be naturally water resistant depending on fabric construction, biomimetic (lotus leaf). Ventile is 100% cotton from WW2, it cracked with wear, not breathable and heavy. Made from long cotton, tight construction, fabric swelling increasing resistance, no additional treatment.

Ecouterre, (2014), waterproof-fabric [ONLINE]. Available at: http://www.ecouterre.com/is-wearable-technology-hype-or-hope/waterproof-fabric/ [Accessed 03 December 14].

- Moisture Management: Thermal Regulation, sportswear/ underwear and domestic, quick to dry and breathable, engineered fibres such as Coolmax and layered membrane protection keeps skin dry and comfortable, drawn from interior to exterior.

Masood, (2006), Unknown [ONLINE]. Available at:http://www.masoodtextile.com/research/special_finishes/special_finishes.php [Accessed 03 December 14].

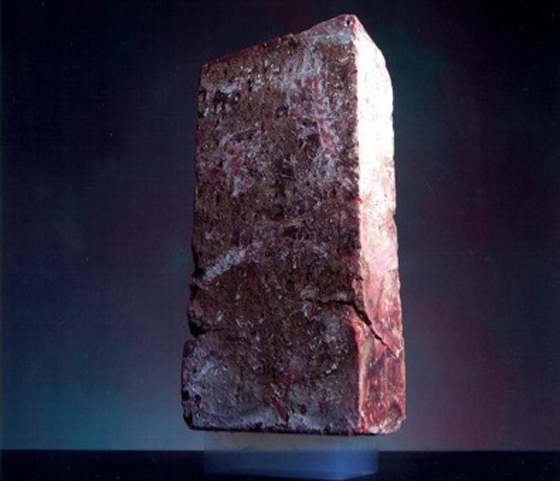

- Temperature: Individually adjusted systems such as AirVantage that builds in air chambers, moist conditions via little blue rings that encourage sweat in certain areas,Omni-freeze ZERO cooler when in hot, Aerogel used by NASA lightest material known to man, medical and emergency possibilities.

Unknown, (2003), brick.on.aerogel [ONLINE]. Available at: http://lifeboat.com/ex/10.futuristic.materials[Accessed 03 December 14].

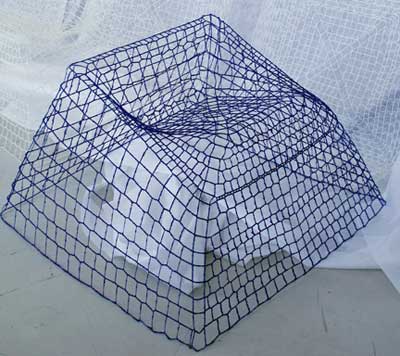

- Buoyancy: Inflatable textiles, protect against sudden impact, air trapping areas into garments, cushioning motorcycle clothing can be automatically activated by sudden movement, temporary installations for housing, exhibitions, architecture and emergency services.

Kengo Kuma, (2002), inflatable teahouse [ONLINE]. Available at:http://www.treehugger.com/sustainable-product-design/inflatable-tea-house-by-kengo-kuma.html[Accessed 03 December 14].

Kengo Kuma created “The teahouse does not rise up from the ground as a fixed wooden construction, but unfolds as an airborne form. When a ventilation system is activated, the teahouse swells into shape like a white high-tech textile blossom. In its interior, comprising a surface of approximately twenty square metres, are nine tatami mats, an electric stove for the water kettle, a tokonoma niche and a preparation room. Integrated LED technology allows the use of the teahouse at night; the interior can be heated by way of the membrane.” it is made from a double layer of 40% light transmitting SEFAR.

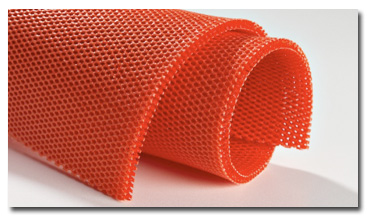

- Anti-static: Minor discomfort but can cause fires, add metal element to fabric or protective finish like copper and silver, safety issues over potentially harmful emissions from mobile phones, pockets developed to have metal to protect the skin

WilkieOffs, (2004), anti_static_air_filtration_bags [ONLINE]. Available at:http://www.wilkieoffshore.co.uk/anti_static_air_filters.html [Accessed 03 December 14].

Signalling Textiles

- Reflective Textiles: Reflecting light for higher visibility at night, embedded glass beads or mini-reflector dishes reflect light to a distance of 200m and even under water, reflective inks/ yarn, Nike’s ‘Reclaim the Night’ collection

Unknown, (2006), thermoreflex1-large [ONLINE]. Available at: http://www.grafityp.co.uk/t-shirt-vinyl-thermoreflex.html [Accessed 03 December 14].

- Refractive Textiles: Fibre produced that changes according to stretch, in-built colour, multiple layers of cells interfere with light waves, as in soap bubble, sportswear changes with muscle tension. Morpho butterfly wings have natural iridescence, developed by Teijin in Japan, many small synthetic fibres layered in alternating direction.

- A biometric colour shift originally found in the hogberry plant. It is where multiple layers of cells interfere with light waves producing an effect akin to a soap bubble, a rainbow. Morpho butterfly wings were an inspiration for fabrics that show colour via the use of phototronics as seen in the company Tejin’s ‘Morphotex’ fabrics. There is a potential use of refractive textiles in sportswear, as they could potentially show visually changes in response to muscle tension, pressure or heat.

- Phosphorescence: Trap and store energy from light to emit a glow, trapped into synthetics, Permalight uses zinc and unsed in printed ink, Rachel Wingfield/ Marmot, electro luminescence that is ‘excited’ by electircal current, Marmot jacket uses EL for display

- Fibres trap and store light energy and emit it as a glow. ‘Permalight’ uses zinc sulphate to do so and is available as a printing ink.

- Fibre Optics: Carry pulses of light powered by source, fibre optic camouflage would enable colour, light and pattern, possible applications in medical textiles

- Chromatic: Able to change their colour in response to external stimuli, thermochromic activated by conductive thread and power source, Maggie Orth, wound heals if it gives off heat, fire fighters uniforms, signal when temperature too high with springs, Squid London

- Pressure Sensitive Film: ‘Bruise suit’ uses a pressure sensitive film developed by Fuji, signal wearer to impact damage to body, offer graduated insight to how damaging an impact

Well-Being Factors

- Easy Care: Treatments that assist in keeping a textile clean. Certain nanotechnologies and Teflon treatments impart stain resistant qualities. There is also the use of non-iron easy care in shirting and bed lined textiles which prevents creases to a certain extent.

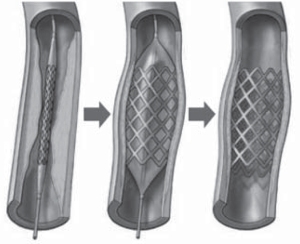

- Comfort and Ease: Medical applications include assisting blood flow and reducing burn scarring, mechanical crimped yarns from synthetic provide gentler comfort and stretch, recovery important

- Aromatic Agents: Scented textiles release aroma when agitated or warmed. Microencapsulation traps the scented particles, aromatherapy elements can also be used, creating multi-sensory textiles and clothing.

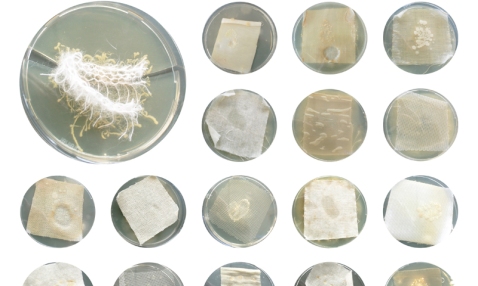

- Anti-Bacterial Protection: Finishes and fibres, found in cosmetics and washing powder, useful for medical/ sports/ footwear, could reduce laundry, naturally derived function found in silver, tea tree and aloe vera as well as crustacean shells

- Insect Repellence: Fabric treatments can assist in reducing the harmful insects that can live in textiles such as dust mites, particularly in bedding, which can be detrimental to the health of asthma sufferers and those with respiratory problems. This is also important to protect young babies before their immune systems develop as they would very easy pick up allergies and develop childhood asthma.

- Catalystic Clothing: A relatively new exploration. Can potentially assist in reducing the harmful effects of air pollution, using nanotechnology that can be applied to the fabric through the laundry process. Effectively when the active agent in the fabric is activated by a catalyst (in this case, air pollution) it will get to work to purify the surrounding air.

Health and Cosmetic Benefits: There are coatings that can be applied to fabrics that are called pollen protection as they have a smooth surface which helps them to shed pollen easily, helping to reduce the effects of hay fever. For a standard t-shirt weighing 200mgs a vitamin C content can be imparted that equals the equivalent of 2 lemons. There are treatments applied to textiles to assist in moisturising skin and delivering active health benefits by trapping moisturising capsules within the fibres. Claims have been made by the likes of Victoria’s Secret and Miss Sixty that wearing their moisture enriched underwear can actively reduce the look and feel of cellulite. How much truth lies in these claims I don’t know.

Interactive Textiles

Conductivity: This is an essential element in interactive textiles. Conductivity can be imparted by the use of metal fibres/content, or with special coatings and printing ink, depending on the product’s use and desired functionality. In conductive gloves fine copper thread in used to complete the electric circuit between skin and screen. Conductive power sources are lightweight and flexible and it is also essential for them to be washable, however solar power elements can be woven into the garment as a back-up power source. Gorix is a branded, carbonised fibre with electrical conductive properties used for heated car sets, motorbike clothing and heated diving suits.

Dominique Lafond, (2009), Unknown [ONLINE]. Available at:http://www.pinterest.com/pin/570760952749272432/ [Accessed 03 December 14].

Soft Interfaces: using textiles as a carrier, the development of ‘ambient technology’ plans to create products for the home that are soft and tactile. Furniture that can ‘memorise’ personal preferences and then adapt accordingly.

Power Sources: Lightweight textile-compatible/ flexible/ reliable/ washable power sources are essential, solar power elements can be woven into garment or added to surface but can be unreliable and used better in backpack, CG chem/ Scott Erest, heat and kinetic energy created by wearer, ‘string’ battery to be used as a piping trim on a product of garment. Korea Advanced Institute of Science and Technology, Fudan University

Monitoring and Health: The Lifeshirt can record the wearer’s vital signs and record it as data via sensors within the garment. This same technology can be used to also monitor emergency workers. it is also used in sport to monitor training, it allows realtime interaction during activity and also provides direct feedback. Can also be used as personal protection via GPS and garments that can shock an attacker. The GPS technology could also track the location of those with health issues in case they come into danger.

Communication and Interaction: Textile keyboards and touch pads, those with disabilities, personal protection via GPS, active camouflage using fibre optics, invisibility clothing and optical camouflage. Metamaterials, electromagnetic composites, allow waves to move around the edge, TUFTS University

Optical camouflage: is also under development, to create camouflage that has an instinctive chameleon effect. Intelligent camouflage built using nanotechnology have the possible ability to divert light wavelengths, to change light from positive to negative refraction, rendering the object invisible.

Fashion: Wearable electronic developments, real integration builds interactivity invisibly into garments, accessories or jewellery. Phillips Bubelle dress, two layers: inner contains biometric sensors, responds to emotions and projects to outer layer as colours.

Bibliography

Dominique Lafond, (2009), Unknown [ONLINE]. Available at:http://www.pinterest.com/pin/570760952749272432/ [Accessed 03 December 14].

Ecouterre, (2014), waterproof-fabric [ONLINE]. Available at: http://www.ecouterre.com/is-wearable-technology-hype-or-hope/waterproof-fabric/ [Accessed 03 December 14].

Kengo Kuma, (2002), inflatable teahouse [ONLINE]. Available at:http://www.treehugger.com/sustainable-product-design/inflatable-tea-house-by-kengo-kuma.html[Accessed 03 December 14].

Masood, (2006), Unknown [ONLINE]. Available at:http://www.masoodtextile.com/research/special_finishes/special_finishes.php [Accessed 03 December 14].

Revzilla, (2008), icon_device_textile_jacket_detail [ONLINE]. Available at:http://blog.revzilla.com/2012/08/icon-device-leather-and-textile-jacket.html [Accessed 03 December 14].

Textile World, (2009), SpecialtyDowSrange [ONLINE]. Available at:http://www.textileworld.com/Issues/2009/July-August/Nonwovens-Technical_Textiles/Observations_Of_Changing_Technology [Accessed 03 December 14].

Unknown , (2000), Masood Textile Mills [ONLINE]. Available at:http://www.masoodtextile.com/research/special_finishes/special_finishes.php [Accessed 03 December 14].

Unknown , (2004), Scotch_Guard_Flame_Retardant_On_Fabric_Shield [ONLINE]. Available at:http://www.alibaba.com/product-detail/Scotch-Guard-Flame-Retardant-On-Fabric_114863836/showimage.html [Accessed 03 December 14].

Unknown, (2003), brick.on.aerogel [ONLINE]. Available at: http://lifeboat.com/ex/10.futuristic.materials[Accessed 03 December 14].

Unknown, (2006), thermoreflex1-large [ONLINE]. Available at: http://www.grafityp.co.uk/t-shirt-vinyl-thermoreflex.html [Accessed 03 December 14].

WilkieOffs, (2004), anti_static_air_filtration_bags [ONLINE]. Available at:http://www.wilkieoffshore.co.uk/anti_static_air_filters.html [Accessed 03 December 14].